Finding the right aluminum die casting manufacturer can be like searching for a modern-day alchemist. You need a partner who can turn liquid aluminum into parts that are strong and lightweight, challenging performance limits. Here is what you should look for:

Expertise Beyond the Mold

Do not settle for a manufacturer with impressive die casting machines; find somebody who has worked in your industry before. Whether it’s building high-performance bicycles or aerospace components, they must understand material properties and application-specific challenges.

Imitation vs Innovation

The best aluminum die casting manufacturers are always looking to push boundaries – not just copying existing designs. This means playing around with new alloys and design techniques that could optimize performance further; collaborate with such a partner to see what more can be done together.

Quality is Everything

In many cases, aluminum die castings play crucial roles in ensuring final products perform well and safety levels are met. Choose manufacturers who enforce strict quality controls from material testing through to thorough inspections of finished goods; ISO 9001 certification would also help.

China’s Manufacturing Might on Global Scale: While it’s true there are many Chinese companies producing aluminum die casts at competitive prices, think big! Why not work with one having operations all over the world? That way you get exposed to cutting-edge technology from other regions while still benefiting from China’s cost advantages.

Talk Freely: No partnership succeeds unless both parties communicate openly throughout every stage of production – including after-sales service provision too. Find manufacturers known for frequent project updates sharing as well as readily addressing concerns raised by clients like yourself; create an environment where ideas flow easily towards realization into high-performance aluminum die-cast products.

By considering these points, you will identify an aluminum die casting manufacturer who goes beyond being just another vendor but rather becomes an integral part of value chain creation aimed at realizing performance-driven goods.

Injection Mold China: Unveiling Precision and Potential Beyond Cost Savings

There’s no denying that China is the undisputed king when it comes to injection molding. However, most people only see this from a cost perspective. Here are some tips for unlocking its full potential:

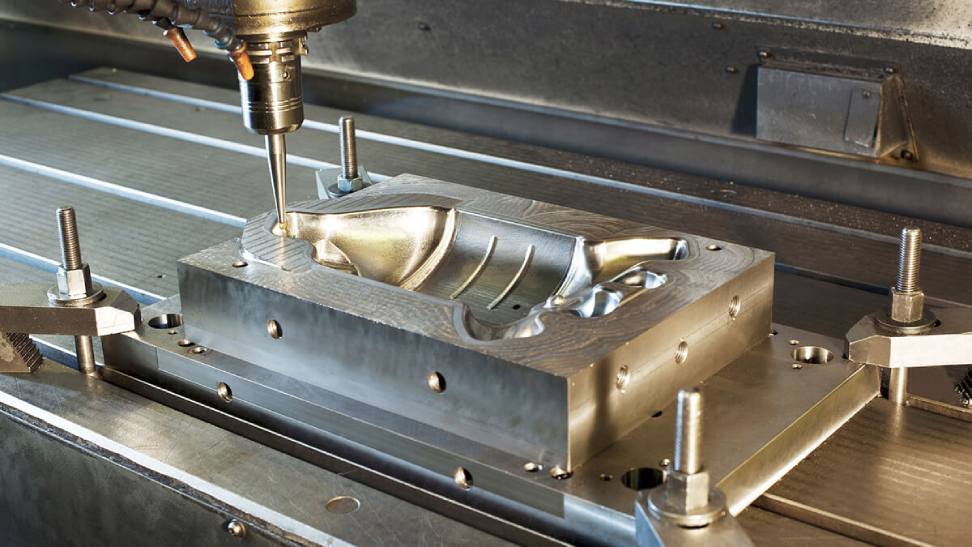

Preciseness is Key: Injection molding isn’t simply about producing large numbers of parts; it entails making very detailed plastic components as well. Ensure the manufacturer has advanced mold-making capabilities and focuses on precision too – your pieces should meet tight tolerances consistently without fail.

Material Science: A wide range of thermoplastics can be used in injection molding, each having its own unique characteristics. Work with a company that will assist you in selecting the best material for your desired application; strength, heat resistance or flame retardance may all be necessary depending on what you want to achieve.

Out-of-the-Box Thinking: The most innovative injection mold China in China do not limit themselves to what already exists out there. They keep exploring new technologies like multi-shot molding or in-mold decorating which allow them create more complex parts with improved functionality and aesthetics simultaneously.

Quality Assurance at Every Step: Quality control should begin right from when raw materials arrive up until finished products leave factory gates; documented procedures must be followed therefore using automated inspection systems where applicable is advisable.

Sustainability Matters Too: While it’s important to consider costs, also think about environmental friendliness during supplier selection process. Some manufacturers use recycled inputs while others optimize energy consumption or adopt responsible waste management techniques hence such options could save money over time.

Elevate China’s injection molding capabilities from a cost-saving measure to a strategic advantage by focusing on these areas. You will be able to get plastic components that are high quality and have increased functionality for your product because they are precise, creative and environmentally friendly in nature.

Summary

China is known for its knack in manufacturing. In this article, we will take a closer look at two of the most important processes; aluminum die casting and injection molding. Both are used to make parts on a large scale, but each has its own strong points.

Aluminum die casting suppliers work towards producing lightweight yet strong parts from liquid aluminum which can be used in applications that require high performance such as automobiles or aerospace industries . Choosing the right partner demands considering their knowledge in the sector, commitment to invention and strictness in quality assurance among other things. There are many manufacturers within China however one should also consider looking out for those companies which have international presence so that they may gain an opportunity of accessing cutting edge technology.

Also Read:

- Types Of Food Label Printers

- Copyleaks – AI Content Detector

- What Is Runway AI? How To Use?

- Wellsaid Labs – Ai Voice Generator